Publications

| Title | Date | Author | Download |

| A Link Between the Lab and the Real World - A Setup for Accelerated Aging of Power Electronics Using Mission Profiles from the Field | 2025 04 09 | Mattias P. Eng, Madhav Mishra, Wilhelm Söderkvist Vermelin, Dag Andersson and Klas Brinkfeldt | Link |

| A more appropriate testing method for the characterization of dielectric systems in power modules (EIC2024) | 2024 06 05 | P. Seri, D. Demian, A. Reolon, A. Cavallini | Link |

| A Novel Approach to Ensure Reliable EMI Performance: Identifying and Mitigating EMI Challenges in Fast Switching Power Converters | 2024 10 03 | Tabish Ahmad, Jurgen Willaert, Przemyslaw Misiewicz, Jean-Paul Linnart | Link |

| A Review on Gate Oxide Failure Mechanisms of Silicon Carbide Semiconductor Devices | 2024 10 25 | J. Li, A. Shekhar, W. D. van Driel and G. Zhang | Link |

| Acoustic emission-based prognostics of power semiconductor modules (Master’s Thesis) | 2024 05 04 | Tapio Leppänen | Link |

| Analysis of the Thermo-mechanical Performance of Double-Sided Cooled Power Modules | 2024 05 10 | Bhanu Pratap Singh, Shahriar Sarmast Ghahfarokhi, Konstantin Kostov, Hans-Peter Nee, Staffan Norrga | Link |

| Analytical prediction of the thermal behavior of semiconductor power devices from room temperature I-V measurements | 2024 03 14 | Sandor Ress, Gabor Farkas and Marta Rencz | Link |

| Assessment of Parameter Identification Methods for Digital Twins of Two-Level Bidirectional Converters | 2024 11 20 | Parsa Behzad Nazif; Saad Ahmad; Mariam Saeed; Juan M. Guerrero; David Ortega; Beñat Zelaa, Larrazabal, Igor, Briz, Fernando | Link |

| Collaborative Training of Data-Driven Remaining Useful Life Prediction Models Using Federated Learning | 2024 10 04 | Wilhelm Söderkvist Vermelin, Madhav Mishra, Mattias P. Eng, Dag Andersson, and Konstantinos Kyprianidis | Link |

| Comparison of Multi-level Topologies to Reduce the Components Voltage Stresses when Powered from Industrial DC Grids | 2024 06 1 | Katharina Machtinger, Peter Jonke, Ulrich Boeke | Link |

| Deskewing Method for Double Pulse Test and Loss Calculation in High-Power SiC Modules | 2024 09 06 | Shahriar Sarmast Ghahfarokhi, Bhanu Pratap Singh, Enes Ayaz, Staffan Norrga, Mats Leksell, Marcus Jackson, Hans-Peter Nee | Link |

| Environmental Impact Assessment Tool for Electronics (Master’s Thesis) | 2024 07 30 | Yana Zhabura | Link |

| Evaluation of Possible Traction Inverter Topologies for Heavy-Duty Electric Vehicles | 2025 12 05 | Enes Ayaz, Marcus Jackson, Shahriar Sarmast, Bhanu Singh, Staffan Norrga, Hans-Peter Nee | Link |

| Experimental Evaluation of a Gate-Step-Response Method for Device Identification used in Self-Configurable Gate-Drive Units | 2024 09 06 | Marcus Jackson, Enes Ayaz, Shahriar Sarmast Ghahfarokhi, Bhanu Pratap Singh, Hans-Peter Nee, Staffan Norrga, Tomas Jonsson, Jang-Kwon Lim, Konstantin Kostov | Link |

| Fatigue Crack Networks in Die-Attach Layers of IGBT Modules Under a Power Cycling Test | 2024 08 22 | Shenyi Liu , Vesa Vuorinen , Xing Liu , Olli Fredrikson, Sebastian Brand, Nikhilendu Tiwary , Josef Lutz , and Mervi Paulasto-Kröckel | Link |

| Friction and wear in journal bearings: accurate testing and simulation with an outlook on predictive maintenance with machine learning | 2023 09 27 | Sophia Bastidas and Hannes Allmaier | Link |

| Impact of semiconductor device selection on resource and energy efficiency of power converters | 2023 09 25 | Juuli Leppänen | Link |

| Life Cycle Assessment of Power Semiconductor Module Manufacturing (Master´s Thesis) | 2023 07 21 | Mostafa Radwan | Link |

| Mechanical parameter identification for soft potting materials used in frame-based power modules (EurosimE) | 2025 04 09 | Nafiz Söyleyen, Tatyana Kashko, Markus Hillgärtner and Jonas Wirries | Link |

| Priority-Based DC-Link Voltage Control for Railway Traction Chains With Onboard Energy Storage | 2024 11 18 | Saad Ahmad; Mariam Saeed; Juan Manuel Guerrero; Iker Muniategui-Aspiazu; Guillermo Nuñez; Igor Larrazabal | Link |

| Onboard Energy Storage Systems for Railway: Present and Trends | 2023 07 06 | Mariam Saeed; Fernando Briz; Juan Manuel Guerrero; Igor Larrazabal; David Ortega; Victor Lopez | Link |

| Performance Analysis of Energy-Efficient Path Planning for Sustainable Transportation | 2024 06 10 | Dimitrios Georgiadis, Konstantina Karathanasopoulou, Cleopatra Bardaki, Ilias Panagiotopoulos, | Link |

| Preliminary characterization of dielectrics for insulated metal substrates (IMS) of power modules (ICD2024) | 2024 06 10 | P. Seri, D. Demian, A. Reolon, A. Cavallini | Link |

| Privacy Auditing Schemes in Differential Private Machine Learning: The Current Trends | 2025 01 10 | Ivars Namatevs, Kaspars Sudars, Arturs Nikulins, Kaspars Ozols | Link |

| Product carbon footprint life cycle assessment of Kempower Satellite and Kempower Power Unit | 2024 | Vauhkonen, Veikka | Link |

| Single Event Effects in 3.3 kV 4H-SiC MOSFETs Due to MeV Ion Impact Solid State Phenomena 361 | 2024 04 05 | Zimo Yuan, Jang-Kwon Lim, Alex Metreveli, Hithiksha Krishna Murthy, Mietek Bakowski, Anders Hallén | Link |

| Investigation of Threshold Voltage Instability and Bipolar Degradation in 3.3 kV Conventional Body Diode and Embedded SBD SiC MOSFET Solid State Phenomena 361 | 2024 08 10 | Hithiksha Krishna Murthy, Jang-Kwon Lim, and Mietek Bakowski | Link |

| Temperature dependent trap characterisation and modelling of silicon carbide MOS capacitor | 2024 04 10 | Jinglin Li, Sten Vollebregt,Yaqian Zhang, Aditya Shekhar, Alexander May, Mathias Rommel,Willem D. Van Driel, Guoqi Zhang | Link |

| Transient thermal measurement with an integrated temperature sensor in a power semiconductor chip (bachelors thesis) | 2024 | Eeli Kerttula | Link |

| Validación experimental de un convertidor resonante aislado para sistemas auxiliares en un tren | 2023 | Giles Vieyra, Joan Elias; Rodríguez Alonso, Alberto; Hernando Álvarez, Marta María; Sebastián Zúñiga, Francisco Javier; Zelaa, B.; Aguirre J.; Castro, A.; Bermejo, J. M.; Ortega, D. | Link |

| 3D-Printed Direct Liquid Multi-Jet Impingement Cooling Solutions for Power Electronics in Electrified Automotive Transportation (THERMINIC) | 2024 09 27 | Reza Moloudi; Bart Vandevelde; Willem Verleysen; Silke G.C. Cleuren; Lucie Masquelet; Maik Sternberg, Adrian Stelzer, Andreas Burghardt, Przemyslaw Jakub Gromala | Link |

| Cradle-to-Gate Life Cycle Assessment of Si IGBT and SiC MOSFET Power Modules | 2024 04 | Mostafa Radwan, Mervi Paulasto-Kröckel, Vesa Vuorinen | Link |

| Demonstration of chip integrated temperature sensor for deterioration monitoring for power semiconductor modules | upcoming | Joonas Leppänen, ABB; et. al. | |

| Early detection of wire bond degradation in IGBT modules using on-chip junction temperature sensor. | 2025 10 | Joonas Leppanen, Atte Hoffren, Tapio Leppanen, Eeli Kerttula, Shenyi Liu, Vesa Vuorinen, Mervi Paulasto Krockel | Link |

| End of life influencing factors for Dual Active Bridge components in Flow Battery Application | 2024 10 03 | Sourabh Singh, Jelle Zeilstra, Aditya Shekhar and Pavol Bauer | Link |

| Magnetic field sensors for non-invasive current monitoring in wire-bond-less power module | 2024 03 27 | Perla Malagò, Stefano Lumetti, Dominik Holzmann, Michael Ortner, Ali Roshanghias | Link |

| Parameter Identification Methodology for Buck Converter Digital Twin Considering Sensors Errors | 2024 06 07 | Behzad Nazif, Parsa and Saeed, Mariam and Ahmad, Saad and Manuel Guerrero, Juan and Rodríguez Mendez, Aitor and Carlos Ozaita Araico, Guillermo and Larrazabal, Igor and Briz, Fernando | Link |

| Verification of Material Models of an Epoxy Mold Compound Used in Power Module | 2024 09 04 | Akshay Vivek Panchwagh, Przemyslaw Jakub Gromala, Sven Rzepka, Bernhard Wunderle | Link |

| Physics-Based Deep Learning for Online and Onboard Prediction of Insulation Degradation Under Variable Stress Conditions | 2025 09 14 | P. Seri, A.Trotta, T. Schafberger, C. Reil, A. Cavallini | Link |

| Algorithm for Current Balancing in Parallel Connected Inverters | 2025 10 25 | Veli-Matti Leppänen | Link |

| Common-Mode Voltage Reduction in Two-Level Inverters by Introducing Adaptive Carrier-Phase-Shift Method | 2025 09 04 | Enes Ayaz, Shahriar Sarmast, Staffan Norrga, Hans-Peter Nee | Link |

| Enhanced Back-to-Back Power-Hardware-in-the-Loop Test-Bed for Heavy-Duty Traction Inverter | 2025 09 | Shahriar Sarmast Ghahfarokhi, Enes Ayaz, Staffan Norrga, Hans-Peter Nee | Link |

| Predictive maintenance of journal bearings: Remaining Useful Lifetime Prediction using Isolation Forest and Temporal Convolutional Networks | 2026 01 29 | Sophia Bastidas, Hannes Allmaier, Alexander Zincke | Link |

| SiC MOSFET Condition Monitoring using Compensated ON-State Resistance for Identifying Package Failures | 2025 09 04 | Bhanu Pratap Singh, Shahriar Sarmast Ghahfarokhi, Enes Ayaz, Hans-Peter Nee, Staffan Norrga | Link |

| Online Junction Temperature Measurement of IGBT Power Modules with Chip-Integrated Sensor | 2025 09 01 | Matthias Meißner, Dirk Rudolph, Sebastian Rode, Steffen Bernet | Link |

| Generalized Analysis of Unregulated Isolated dc-dc Converter for Wide Input Voltage Variations | 2025 09 01 | Joan Giles, Alberto Rodríguez, Aitor Vázquez, Jairo Tuñón, J. M. Bermejo, B. Zelaa, D. Ortega, and Igor Larrazabal | Link |

| Comparative Analysis of Gradient-Based, Metaheuristic and Hybrid Methods for Parameter Identification in Digital Twin for DC/DC Converters | 2025 10 17 | Parsa Behzad Nazif, Mariam Saeed, Saad Ahmad, Iker Muniategui, Igor Larrazabal, Guillermo Ozaita, Fernando Briz | Link |

| Analysis and modeling of voltage unbalance in three level dc/dc converters | 2025 10 17 | Saad Ahmad, Alejandro Fernández, Mariam Saeed, Igor Larrazabal, Fernando Briz | Link |

| Coordinated SSCB and Impedance-Based Restoration Scheme for Islanded Microgrids | 2025 08 | Symeon Fountoukidis, Ioannis Kanimas, Nick Papanikolaou | Link |

Public Deliverables

| Deliverable | Due Date | Creator | Download | |

|---|---|---|---|---|

|

D2.1.5. - Summary Report on results on Cross Application & Domain Topics of methods for reliability, modelling & digital twins

|

Download | |||

|

D2.2.5. - Summary Report on results on Cross Application & Domain Topics of substrates, materials, packaging & cooling

|

Download | |||

|

D2.3.5 - Report on intermediate results on Cross Application & Domain Topics of methods for intelligent sensing and control

|

Download | |||

|

D2.4.5 - Summary Report on results on Cross Application & Domain Topics of tools and measurement

|

Download | |||

|

D 2.5.2. - Summary Report on results on Cross Application & Domain Topics of sustainability

|

Download | |||

|

D3.1.4 - Summary Report on demonstrators along the value chain of the Mobility Use Cases

|

Download | |||

|

D3.2.4 - Summary Report on demonstrators along the value chain of the Use Cases for Renewables, Grids &Lighting

|

Download | |||

|

D3.3.4 - Summary Report on demonstrators along the value chains of the Use Cases for Industrial Drives

|

Download | |||

|

D4.1 - Project website: PowerizeD web portal establishment and operation

|

Download | |||

|

D4.6.2. - Draft Summary Report on Qualification and Standardization

|

Download | |||

|

D4.7.2 - Final Summary Report on Qualification and Standardization

|

Download | |||

|

D5.4 - Data Management Plan

|

Download | |||

|

D5.5 - Updated Data Management Plan

|

Download | |||

|

D5.6 - Data Management Plan

|

Download |

Demonstrators

The PowerizeD demonstrators showcase how digitalisation transforms power electronics across key application domains. Each use case validates innovative solutions that enhance efficiency, reliability, and sustainability, highlighting the project’s real-world impact and contribution to Europe’s green and digital transition.

UC 1.1 - Railway propulsion systems

by: Ganesh Chandramouli

from: Alstom Rail SWEDEN AB

Smart sensing functions in intelligent control and gate drive platform, replacing or augmenting discrete stand-alone sensors using capabilities built into the controller, gate drive, and power semiconductor. Test system and methods for AI enhanced verification of railway propulsion systems, improving reliability and robustness testing of power electronics.

from: Alstom Rail SWEDEN AB

Smart sensing functions in intelligent control and gate drive platform, replacing or augmenting discrete stand-alone sensors using capabilities built into the controller, gate drive, and power semiconductor. Test system and methods for AI enhanced verification of railway propulsion systems, improving reliability and robustness testing of power electronics.

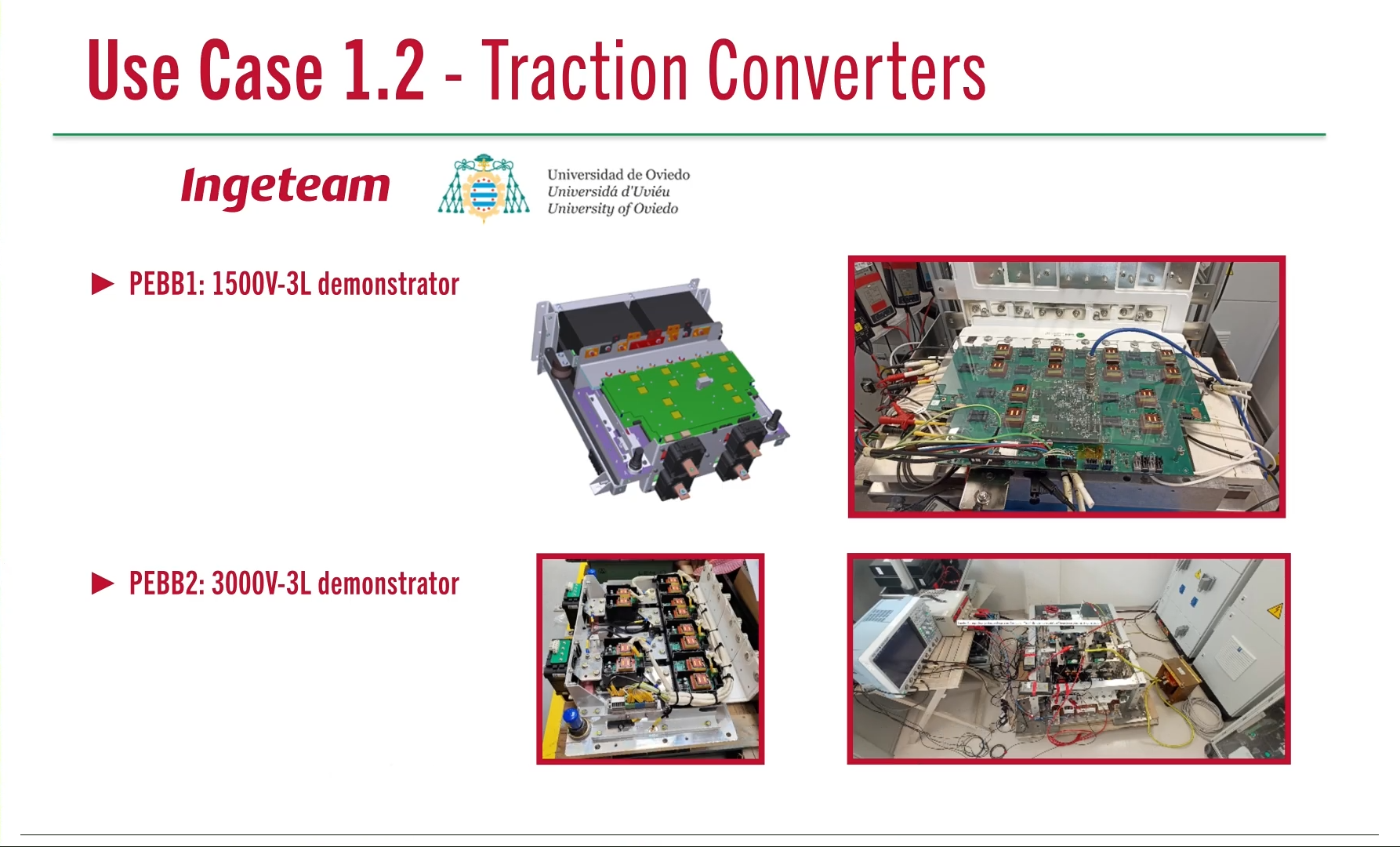

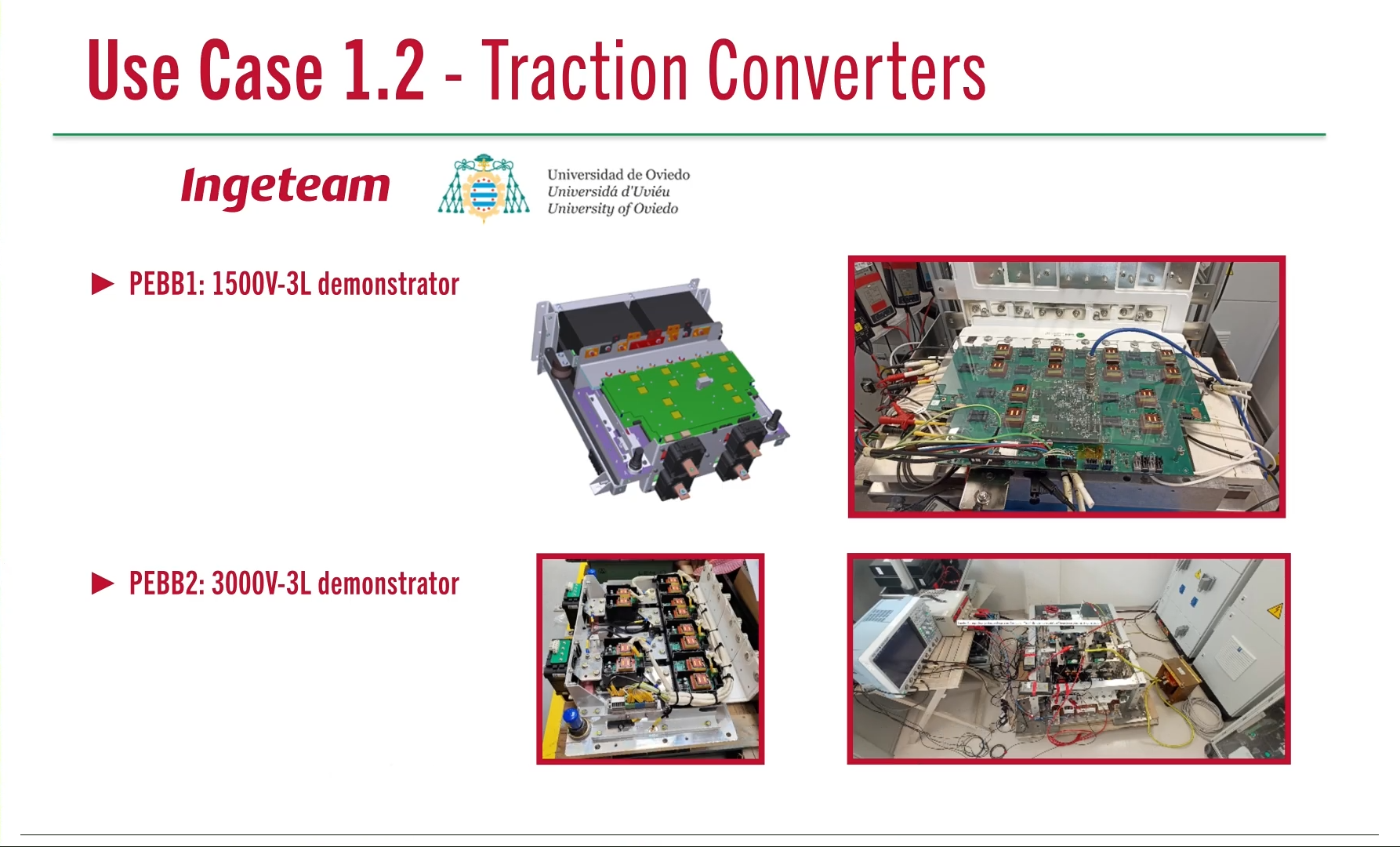

UC 1.2 - Traction Converters

by: Inigo Polo

from: Ingeteam Power Technology SA

In this UC, two Demonstrators have been designed and manufactured for validation of new traction power systems in railway:

Demonstrator 1 (PEBB): The 1500V-3L demonstrator is designed for railway vehicles that operates at nominal 1,5KV DC catenary lines. The PEBB is based in semiconductor package XHP2, LV100 and ANPC topology. As ANPC is more complex than NPC, this PEBB integrates a PMM electronic board that will be connected to TCU. The versatility of this type of PEBB allows fast and custom power systems configurations for specific projects.

Demonstrator 2 (PEBB): The 3000V-3L demonstrator is designed for railway vehicles that operates at nominal 3KV DC catenary lines. The PEBB is based in new semiconductor package XHP3, HV100 and NPC topology. The versatility of this type of PEBB allows fast and custom power systems configurations for specific projects.

from: Ingeteam Power Technology SA

In this UC, two Demonstrators have been designed and manufactured for validation of new traction power systems in railway:

Demonstrator 1 (PEBB): The 1500V-3L demonstrator is designed for railway vehicles that operates at nominal 1,5KV DC catenary lines. The PEBB is based in semiconductor package XHP2, LV100 and ANPC topology. As ANPC is more complex than NPC, this PEBB integrates a PMM electronic board that will be connected to TCU. The versatility of this type of PEBB allows fast and custom power systems configurations for specific projects.

Demonstrator 2 (PEBB): The 3000V-3L demonstrator is designed for railway vehicles that operates at nominal 3KV DC catenary lines. The PEBB is based in new semiconductor package XHP3, HV100 and NPC topology. The versatility of this type of PEBB allows fast and custom power systems configurations for specific projects.

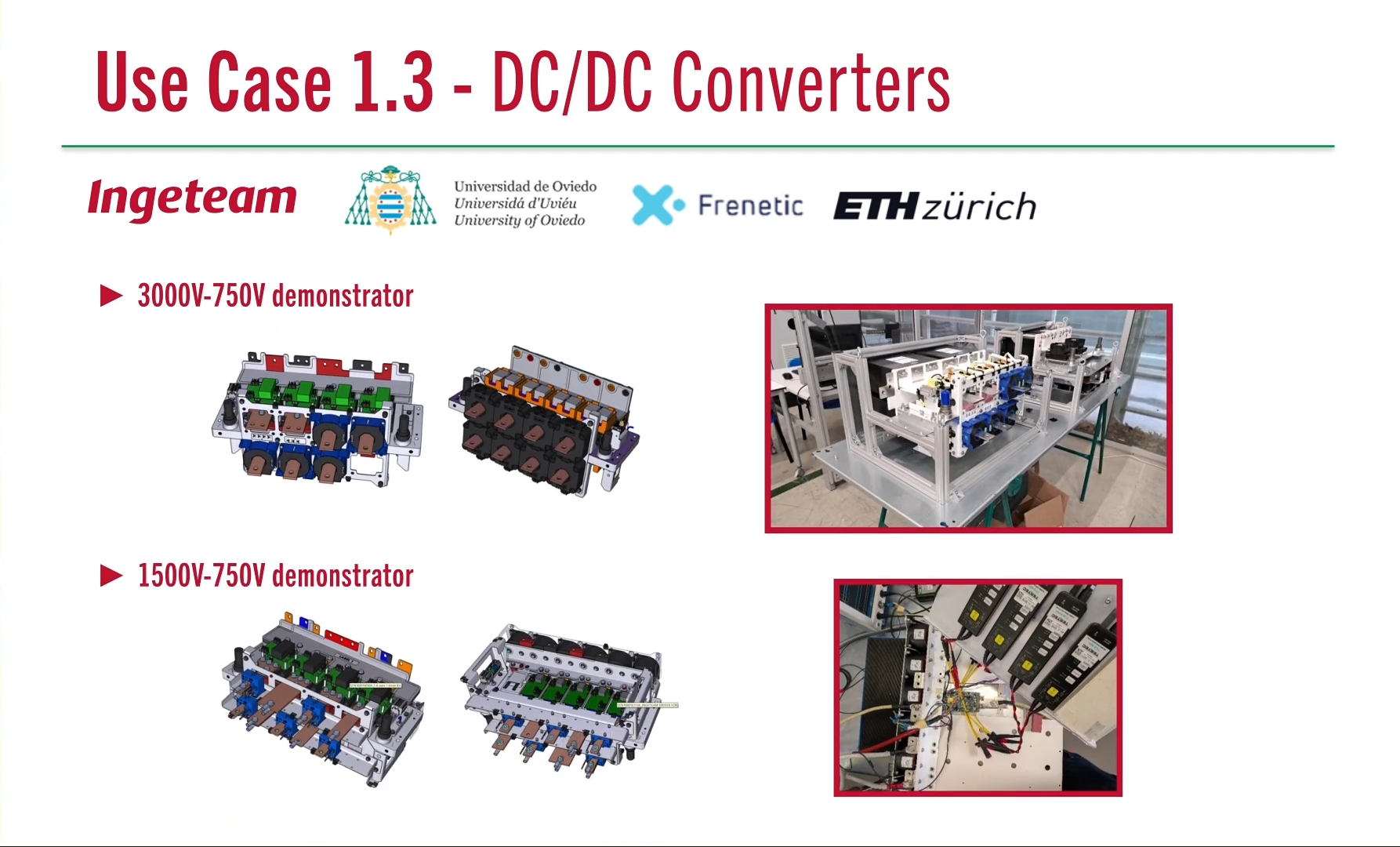

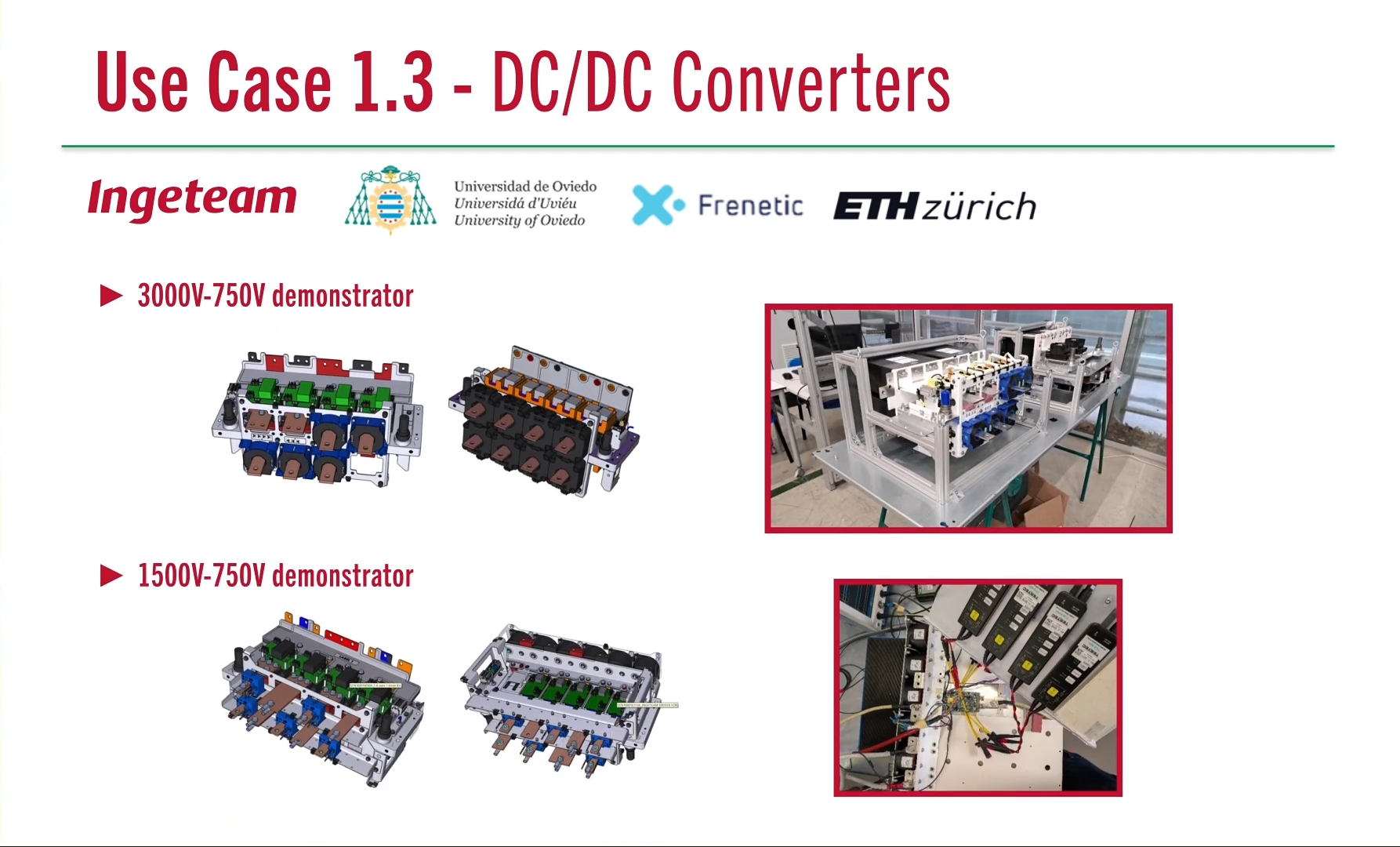

UC 1.3 - DC/DC Converters

by: Inigo Polo

from: Ingeteam Power Technology SA

In this UC, two demonstrators have been designed and manufactured for validation of new auxiliary power systems in railway: Demonstrator 1 (PEBB): Bidirectional resonant converter has been designed to operate between 3kV on the high-voltage side and 750V on the low-voltage side. This system consists of a PEBB incorporating 3.3kV-rated IGBTs in multilevel-level configuration on the high-voltage side, and a second PEBB featuring 1.7kV-rated IGBTs in a two-level configuration on the low-voltage side. The conversion process relies on a medium-frequency transformer and a set of resonant capacitors, achieving 300kW from high voltage to low voltage and vice versa. “Photo demonstrator 1 of UC1.3” Demonstrator 2 (PEBB): Unidirectional resonant converter has been designed to operate between 1.5kV on the high-voltage side and 750V on the low-voltage side. In this configuration, the high-voltage side uses 1.7kV-rated IGBTs arranged in a multi-level topology, while the low-voltage side used the other face of the same PEBB, equipped with 1.2kV-rated IGBTs functioning as diodes in a two-level configuration. Similar to the first demonstrator, this system includes a medium-frequency transformer and a set of resonant capacitors achieving 100kW, only from high voltage to low voltage. “Photo demonstrator 2 of UC1.3”

from: Ingeteam Power Technology SA

In this UC, two demonstrators have been designed and manufactured for validation of new auxiliary power systems in railway: Demonstrator 1 (PEBB): Bidirectional resonant converter has been designed to operate between 3kV on the high-voltage side and 750V on the low-voltage side. This system consists of a PEBB incorporating 3.3kV-rated IGBTs in multilevel-level configuration on the high-voltage side, and a second PEBB featuring 1.7kV-rated IGBTs in a two-level configuration on the low-voltage side. The conversion process relies on a medium-frequency transformer and a set of resonant capacitors, achieving 300kW from high voltage to low voltage and vice versa. “Photo demonstrator 1 of UC1.3” Demonstrator 2 (PEBB): Unidirectional resonant converter has been designed to operate between 1.5kV on the high-voltage side and 750V on the low-voltage side. In this configuration, the high-voltage side uses 1.7kV-rated IGBTs arranged in a multi-level topology, while the low-voltage side used the other face of the same PEBB, equipped with 1.2kV-rated IGBTs functioning as diodes in a two-level configuration. Similar to the first demonstrator, this system includes a medium-frequency transformer and a set of resonant capacitors achieving 100kW, only from high voltage to low voltage. “Photo demonstrator 2 of UC1.3”

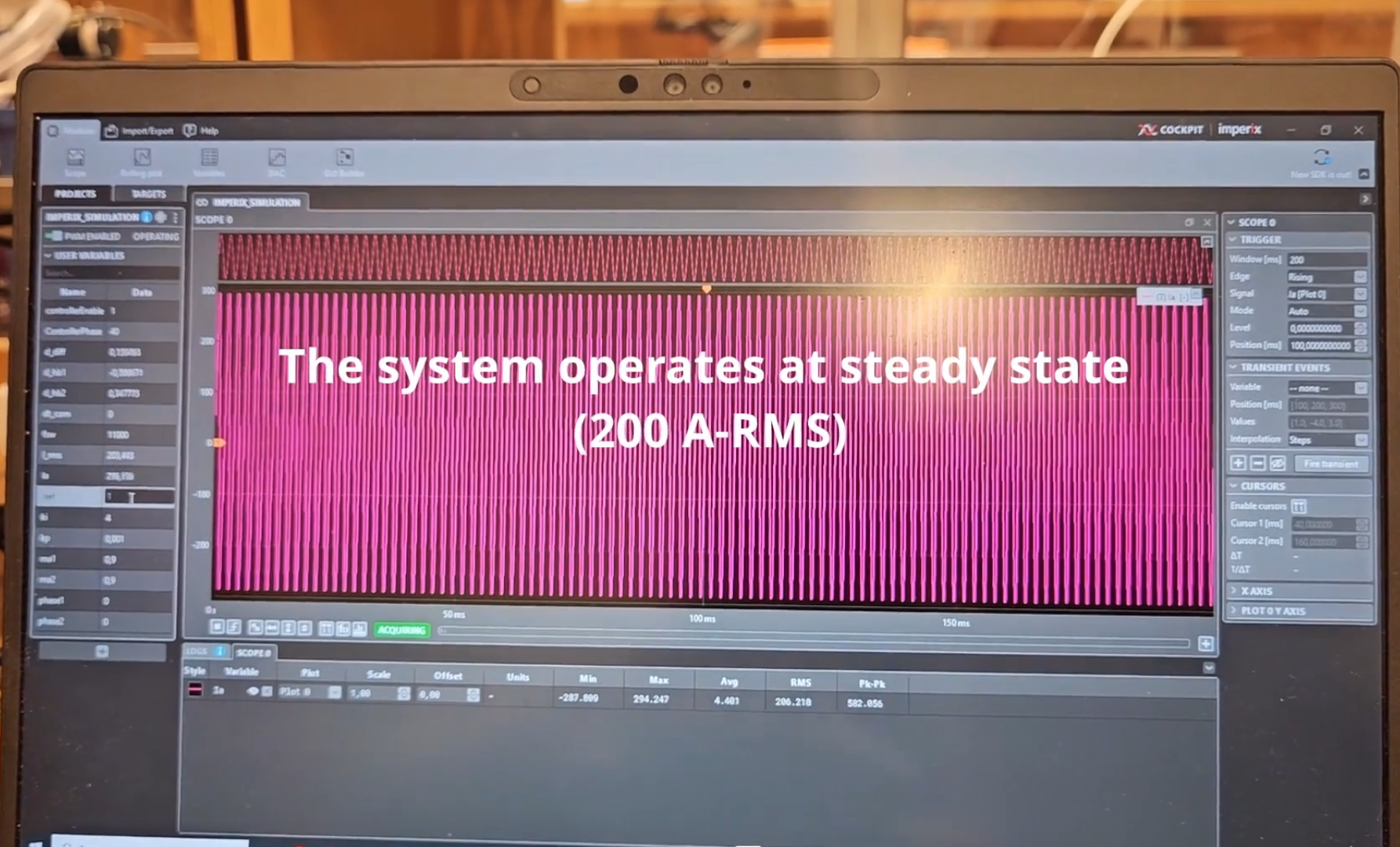

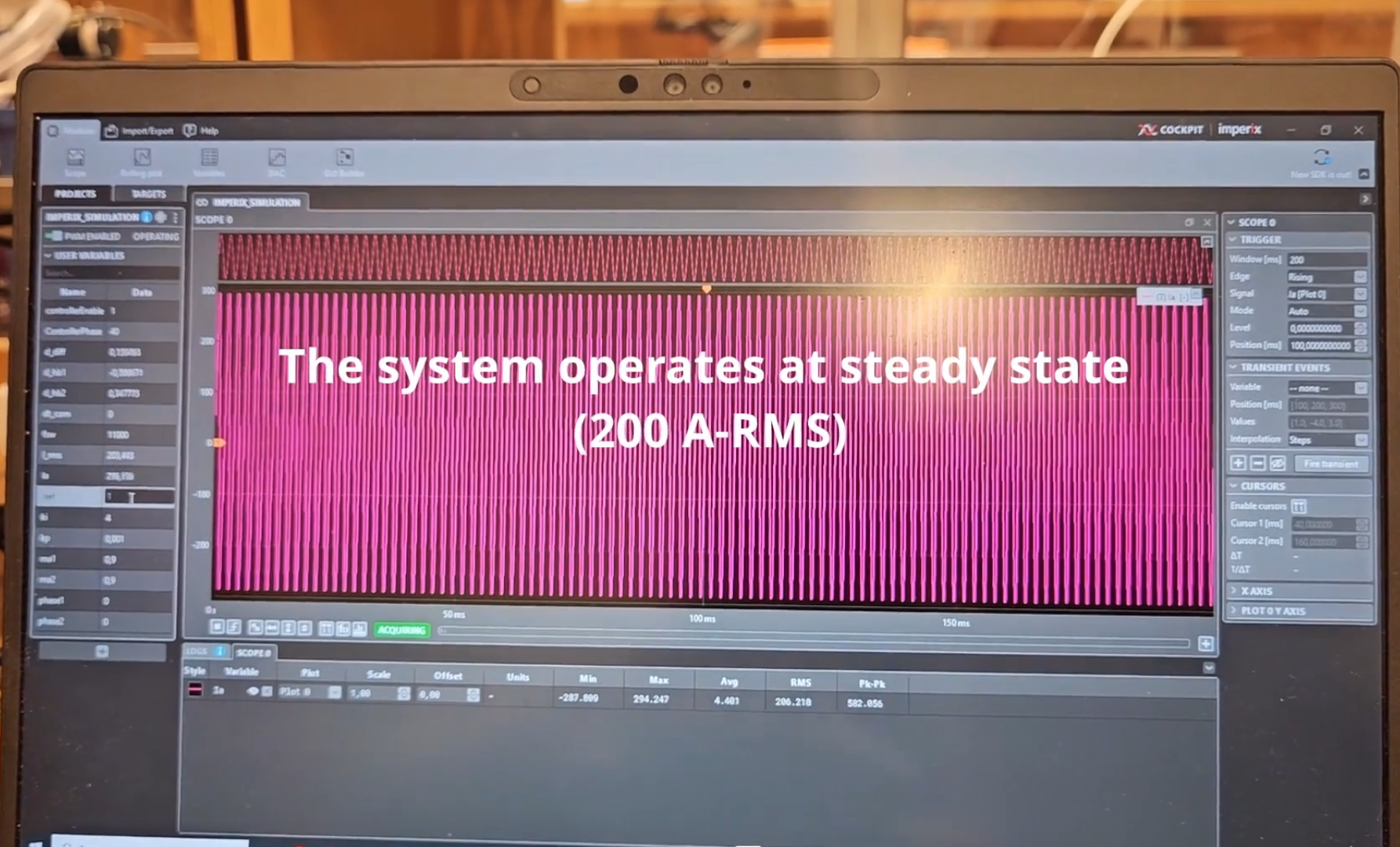

UC 1.4 - BEHDV Drive Inverter for High Voltage - Demo A

by:

from: SCANIA CV AB

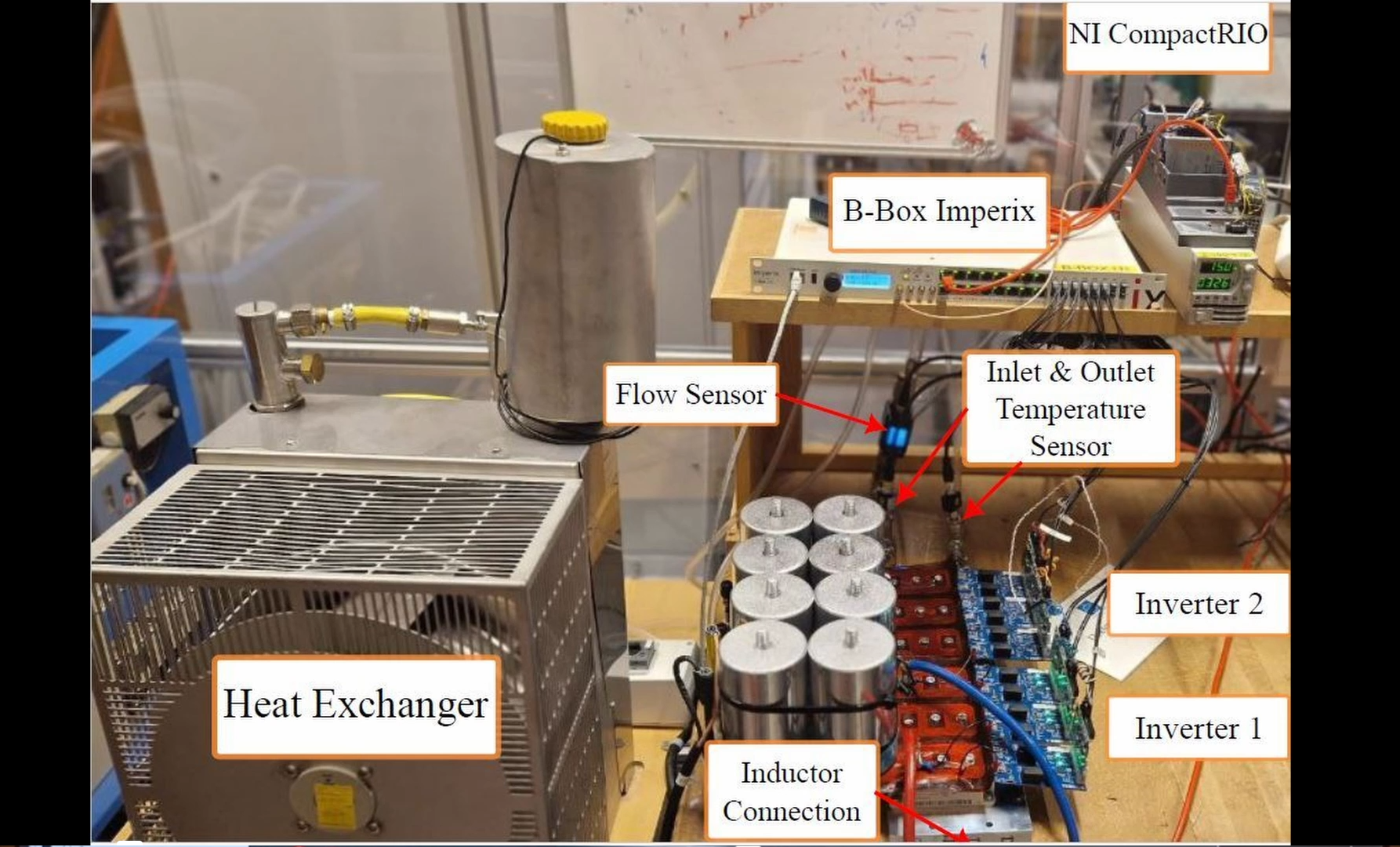

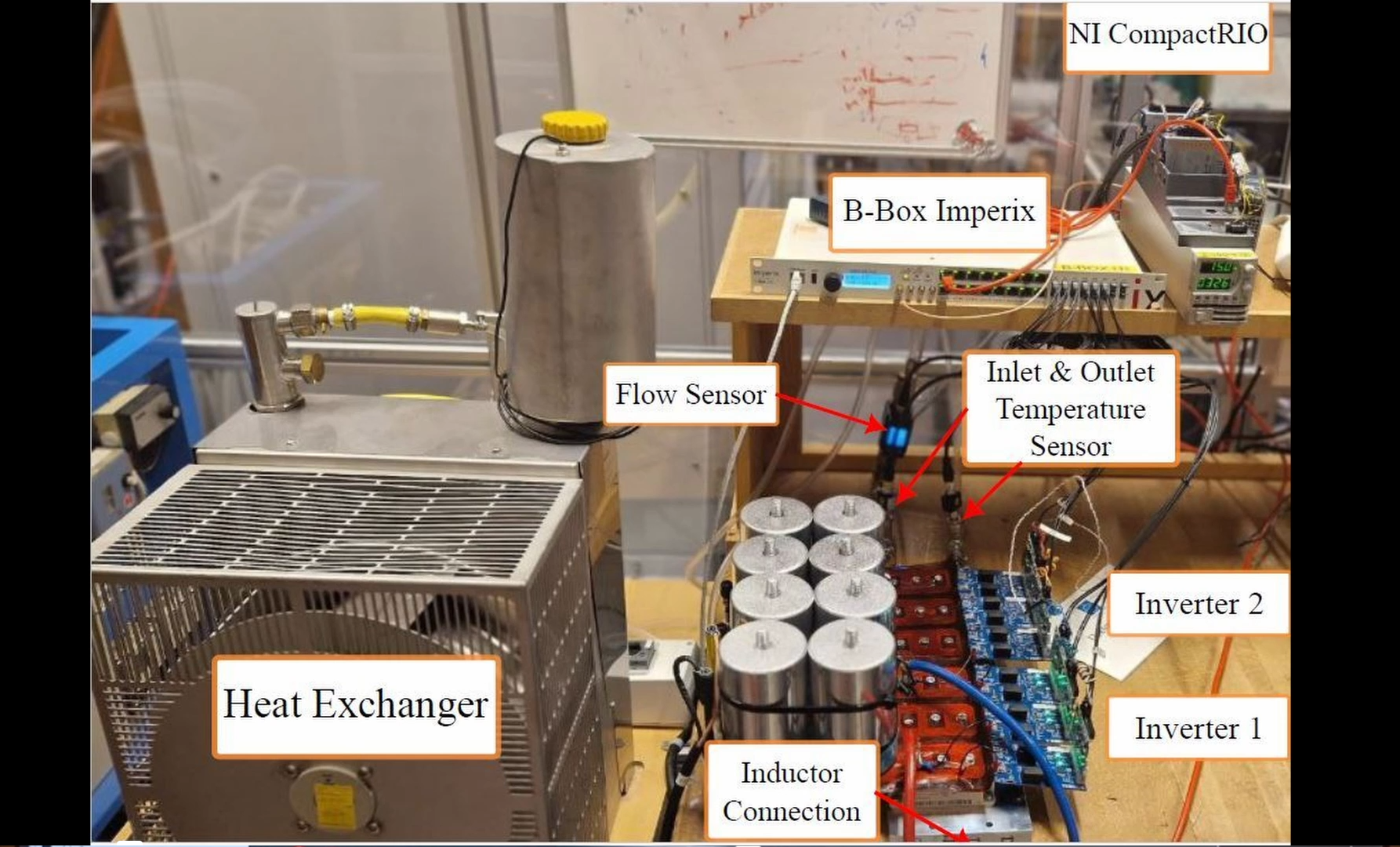

Back-to-Back Inverter Platform A back-to-back (B2B) inverter system has been developed toevaluate the performance of the designed traction inverter undercontrolled laboratory conditions. The setup connects two SiC-basedinverters through a common DC-link, enabling circulation ofcurrent without the need for a motor or high-power supply. Thisdemonstrator allows testing of switching behavior, PWM strategies,phase current control, and DC-link operation across a wide rangeof operating points. “Photo demonstrator 2 of UC1.3”

from: SCANIA CV AB

Back-to-Back Inverter Platform A back-to-back (B2B) inverter system has been developed toevaluate the performance of the designed traction inverter undercontrolled laboratory conditions. The setup connects two SiC-basedinverters through a common DC-link, enabling circulation ofcurrent without the need for a motor or high-power supply. Thisdemonstrator allows testing of switching behavior, PWM strategies,phase current control, and DC-link operation across a wide rangeof operating points. “Photo demonstrator 2 of UC1.3”

UC 1.4 - BEHDV Drive Inverter for High Voltage - Demo B

by:

from: SCANIA CV AB

Calorimetric Loss-Measurement Setup

A dedicated calorimetric testbench has been built to preciselyestimate inverter losses during operation. The setup isolates theinverters thermally and measures heat dissipation with highaccuracy, enabling reliable efficiency assessment at differentswitching frequencies, load conditions, and modulation schemes.This demonstrator complements the B2B platform by providinghigh-precision validation of loss measurements.

from: SCANIA CV AB

Calorimetric Loss-Measurement Setup

A dedicated calorimetric testbench has been built to preciselyestimate inverter losses during operation. The setup isolates theinverters thermally and measures heat dissipation with highaccuracy, enabling reliable efficiency assessment at differentswitching frequencies, load conditions, and modulation schemes.This demonstrator complements the B2B platform by providinghigh-precision validation of loss measurements.

UC 1.5 - FCEV - Fuel cell and powertrain inverter - Demo A

by: Akshay Panchwagh

from: Robert Bosch GmbH

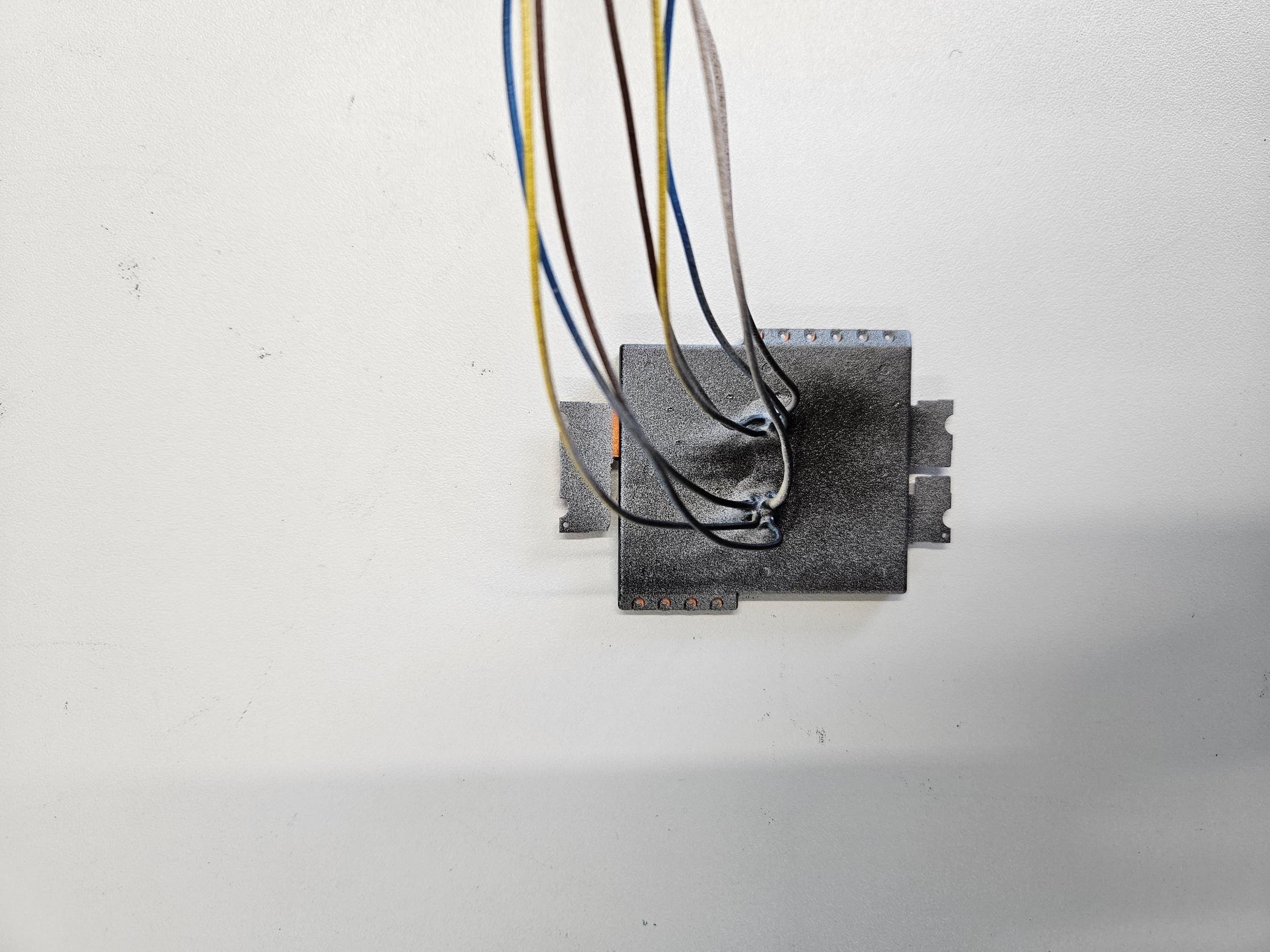

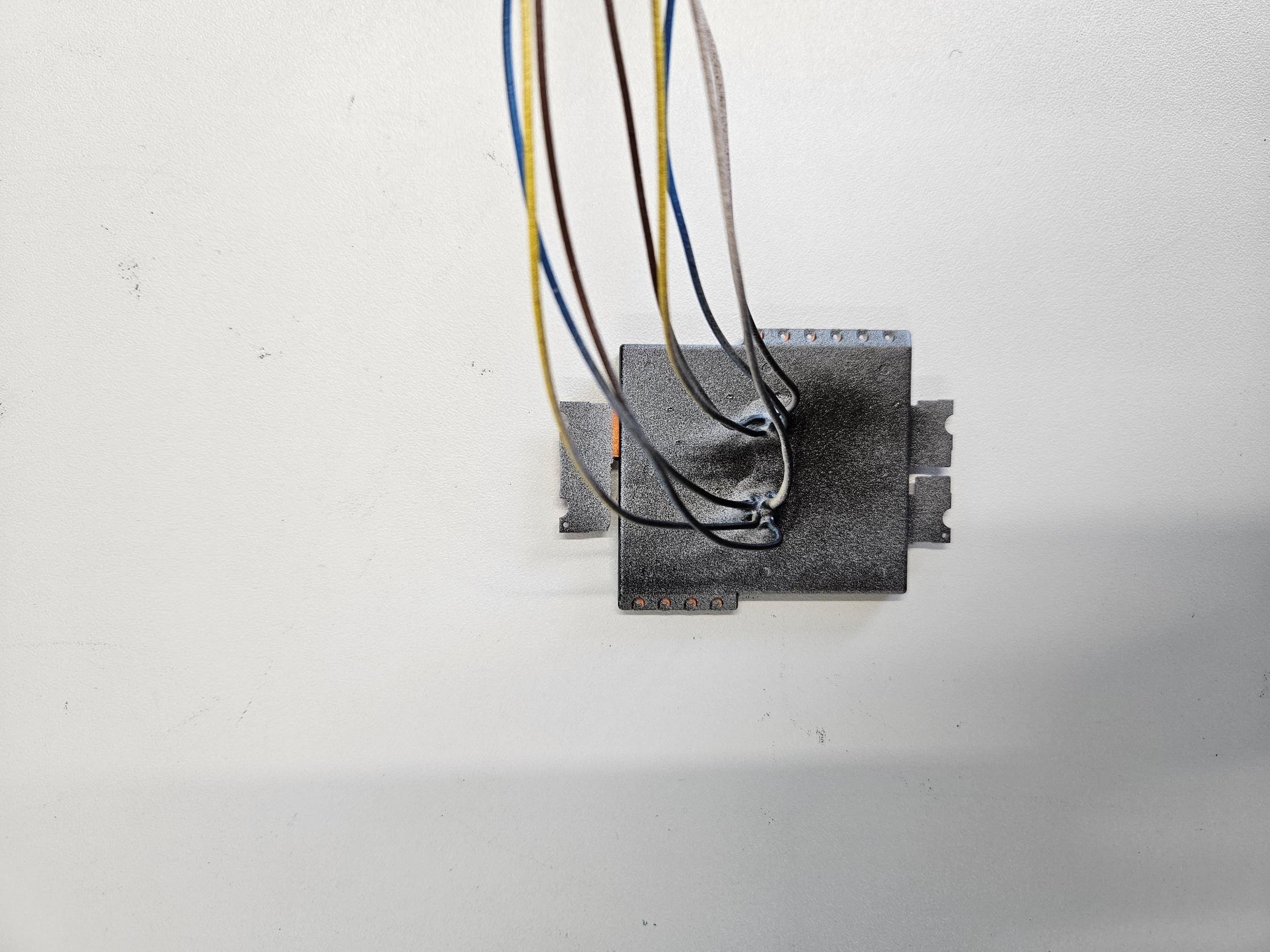

In this use case, a Multi Chip Power Package (MCPP) equipped with a piezoresistive silicon-based stress sensor was used as a demonstrator to highlight the methodology of virtual release through referencing for reduction in development time. For this purpose, two different constructions of the MCPP were used – a B2 bridge and a B6 bridge. The B2 bridge was subjected to passive operating conditions, in which the power package remains inactive while the environmental conditions vary, and the B6 bridge, attached to a cooler, was subjected to active operating conditions in which the power package is actively powered. The aim of using such operating conditions was an accelerated replication of the field conditions, in which the power package operates, and to test the response of the MCPP to such conditions. The demonstrators (B2 and B6 bridges), both equipped with an over-molded piezoresistive stress sensor, (called the iForce sensor) were used to analyze their thermomechanical response to the applied loading conditions and measure stress states within the power package during operations. During both the operations, the warpage response using a Digital Image Correlation (DIC) method, and stresses in the package with the help of iForce sensor were measured. The iForce sensor is a piezoresistive stress sensor, as mentioned previously, which consists of a silicon die of size 1,67 mm x 1,71 mm placed on a Low Temperature Co-Fired Ceramic (LTCC) substrate. Through usage of gold bond wires, it is connected to copper pillars, or pins which help in controlling the sensing cells of the sensor. The sensor used in the demonstrator here has 36 sensing cells. These cells measure stresses in the package with the help of piezoresistive effect of silicon, in which its electrical resistivity changes upon application of stresses. The change is resistivity leads to change in the electrical current which flows through the sensor. The change in these current values helps to calculate the stresses within the package. The aim of measuring these responses was to draw comparisons between experimentally measured values, and their virtual responses to help validate the simulation models, which will be used subsequently as “credible” simulation models.

from: Robert Bosch GmbH

In this use case, a Multi Chip Power Package (MCPP) equipped with a piezoresistive silicon-based stress sensor was used as a demonstrator to highlight the methodology of virtual release through referencing for reduction in development time. For this purpose, two different constructions of the MCPP were used – a B2 bridge and a B6 bridge. The B2 bridge was subjected to passive operating conditions, in which the power package remains inactive while the environmental conditions vary, and the B6 bridge, attached to a cooler, was subjected to active operating conditions in which the power package is actively powered. The aim of using such operating conditions was an accelerated replication of the field conditions, in which the power package operates, and to test the response of the MCPP to such conditions. The demonstrators (B2 and B6 bridges), both equipped with an over-molded piezoresistive stress sensor, (called the iForce sensor) were used to analyze their thermomechanical response to the applied loading conditions and measure stress states within the power package during operations. During both the operations, the warpage response using a Digital Image Correlation (DIC) method, and stresses in the package with the help of iForce sensor were measured. The iForce sensor is a piezoresistive stress sensor, as mentioned previously, which consists of a silicon die of size 1,67 mm x 1,71 mm placed on a Low Temperature Co-Fired Ceramic (LTCC) substrate. Through usage of gold bond wires, it is connected to copper pillars, or pins which help in controlling the sensing cells of the sensor. The sensor used in the demonstrator here has 36 sensing cells. These cells measure stresses in the package with the help of piezoresistive effect of silicon, in which its electrical resistivity changes upon application of stresses. The change is resistivity leads to change in the electrical current which flows through the sensor. The change in these current values helps to calculate the stresses within the package. The aim of measuring these responses was to draw comparisons between experimentally measured values, and their virtual responses to help validate the simulation models, which will be used subsequently as “credible” simulation models.

A B2-Bridge used for combined Warpage-and-Stress Measurement. Cables are connected to Pins of iForce Sensor to extract Stress Data.

A Combined Warpage-and-Stress Measurement of a B2-Bridge During Passive Temperature Cycling.

A B6-Bridge on Cooler with iForce Sensor Pins Visible.

UC 1.5 - FCEV - Fuel cell and powertrain inverter - Demo B

by: Chrisitan Ohms

from: Mercedes Benz

The assembled inverter is derived from a universal platform developed at Mercedes-Benz. It consists of the power electronic semiconductor module, provided by project partner Bosch, a DC-link capacitor, current and voltage sensors, a liquid-cooled heatsink, a gate driver board and a controller board. The power module is a Bosch CSL-1200-355-PS module, capable of a continuous current of 355A and a maximum blocking voltage of 1200V, making it a suitable choice for appliances in automotive 800V-drivetrains. The DC-link capacitor has a total capacity of 600µF. The gate driver board is tailored for the Bosch EG120 driver chip, which allows to define a number of up to 133 different gate current profiles. This feature allows to select the most appropriate gate current profile for a large number of different operation points, with regard to switching losses and safe operation area. Finally, the demonstrator is equipped with a Texas Instruments C2000 microcontroller, a 32-bit dual CPU device with 200MHz clock, 2x512KB flash memory, numerous digital interfaces such as SPI, I2C, CAN, CAN FD and USB2.0, 32 PWM channels and four Analog-to-Digital converters with 24 single-ended inputs. The demonstrator serves as a platform for the PHM and digital twin algorithms developed by the project partners.

from: Mercedes Benz

The assembled inverter is derived from a universal platform developed at Mercedes-Benz. It consists of the power electronic semiconductor module, provided by project partner Bosch, a DC-link capacitor, current and voltage sensors, a liquid-cooled heatsink, a gate driver board and a controller board. The power module is a Bosch CSL-1200-355-PS module, capable of a continuous current of 355A and a maximum blocking voltage of 1200V, making it a suitable choice for appliances in automotive 800V-drivetrains. The DC-link capacitor has a total capacity of 600µF. The gate driver board is tailored for the Bosch EG120 driver chip, which allows to define a number of up to 133 different gate current profiles. This feature allows to select the most appropriate gate current profile for a large number of different operation points, with regard to switching losses and safe operation area. Finally, the demonstrator is equipped with a Texas Instruments C2000 microcontroller, a 32-bit dual CPU device with 200MHz clock, 2x512KB flash memory, numerous digital interfaces such as SPI, I2C, CAN, CAN FD and USB2.0, 32 PWM channels and four Analog-to-Digital converters with 24 single-ended inputs. The demonstrator serves as a platform for the PHM and digital twin algorithms developed by the project partners.

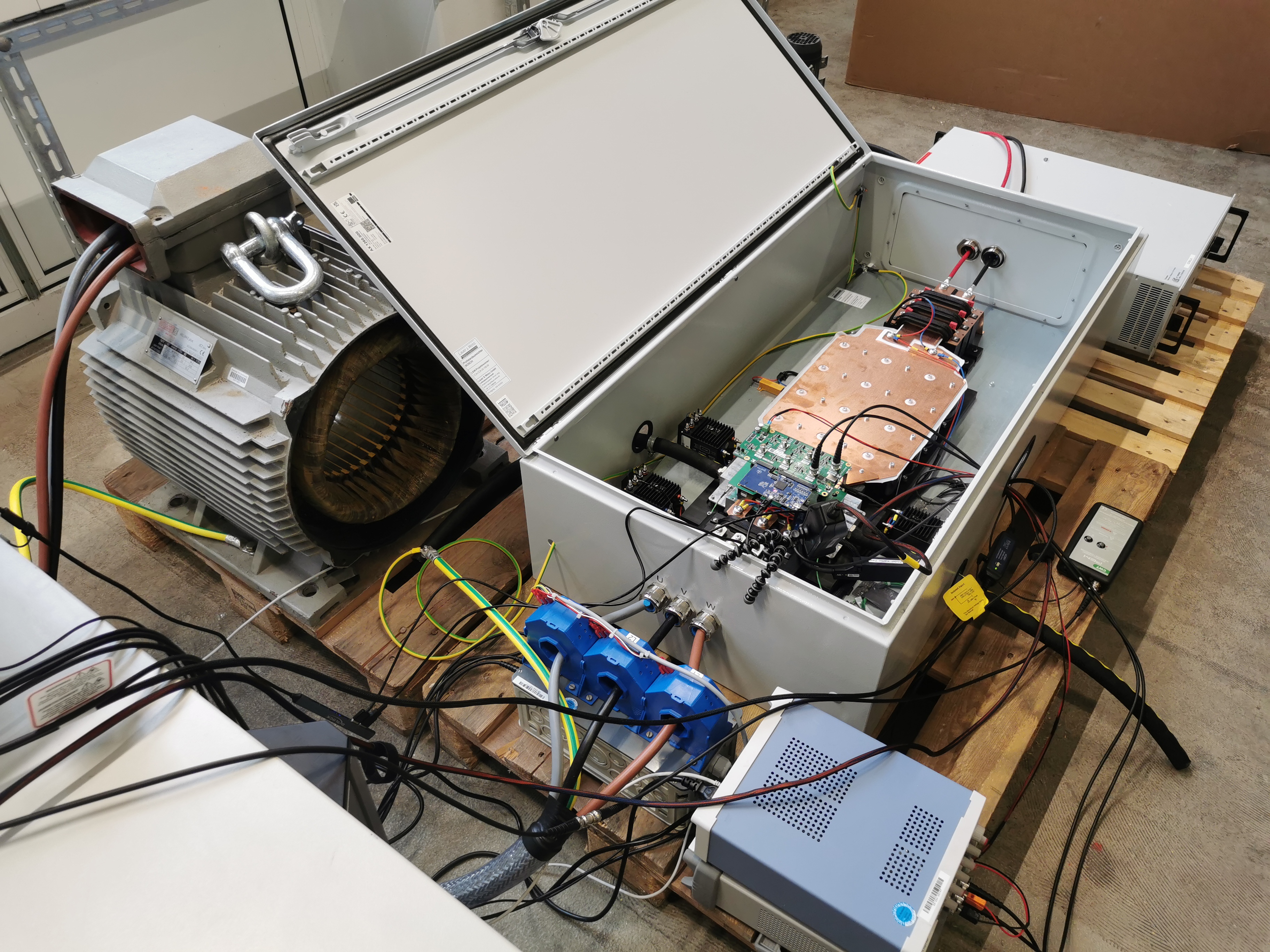

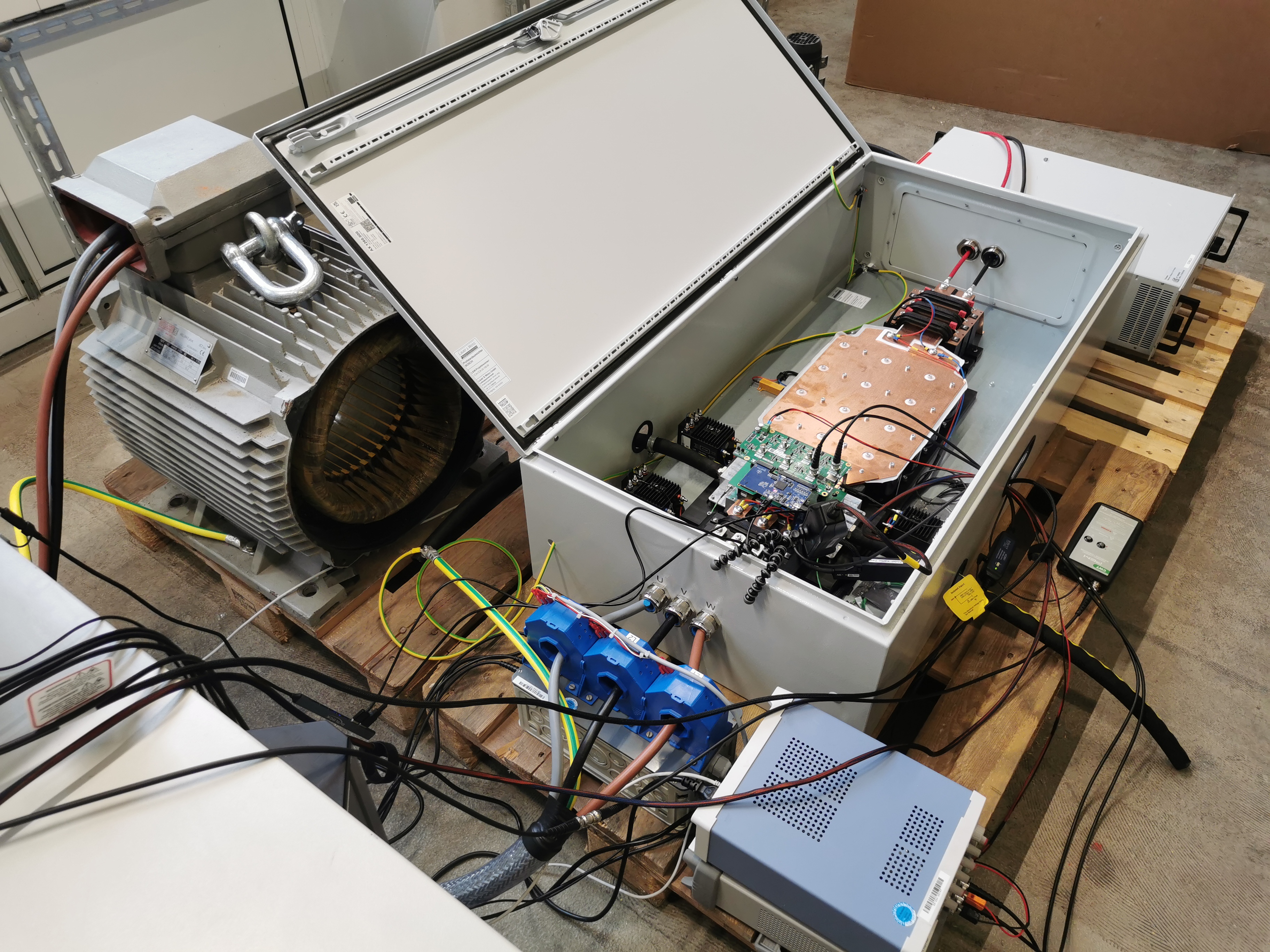

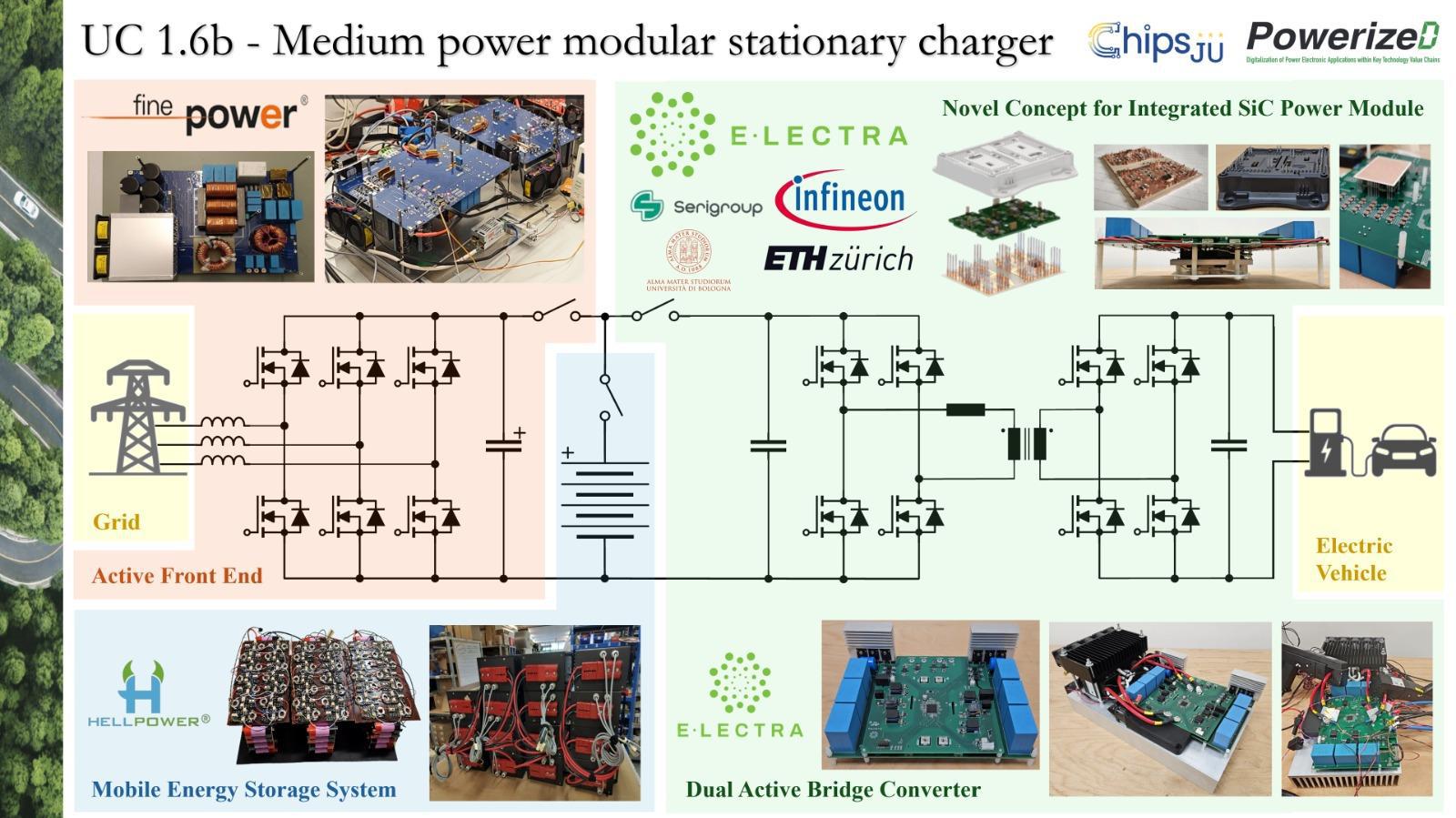

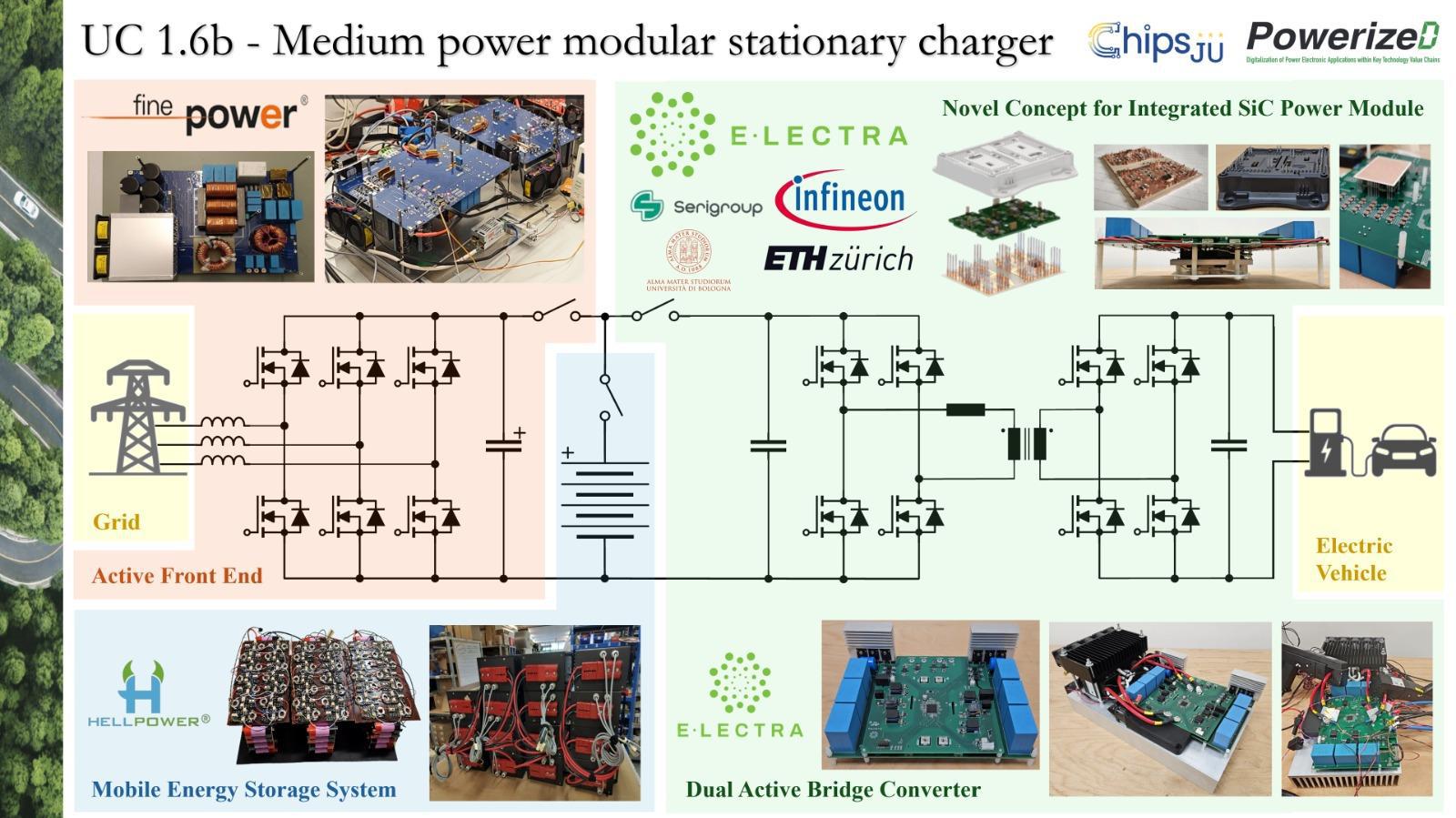

UC 1.6b - Medium power modular stationary charger

by: Francesco Porpora

from: E-Lectra s.r.l.

This use case developed devices and demonstrators for a medium-power bidirectional charging infrastructure for high-voltage electric vehicles, capable of enabling Vehicle-to-Grid (V2G) functionality. Specifically, considering a dual-stage conversion architecture with an integrated mobile and high-voltage battery pack, demonstrators were designed and experimentally validated for each main subsystem that composes the charging infrastructure.

from: E-Lectra s.r.l.

This use case developed devices and demonstrators for a medium-power bidirectional charging infrastructure for high-voltage electric vehicles, capable of enabling Vehicle-to-Grid (V2G) functionality. Specifically, considering a dual-stage conversion architecture with an integrated mobile and high-voltage battery pack, demonstrators were designed and experimentally validated for each main subsystem that composes the charging infrastructure.

- Novel 1200-V SiC-based Intelligent Power Module (IPM) It integrates all the power devices of a Dual Active Bridge (DAB) converter and the related gate driver circuitry in a single compact housing, ensuring proper insulation between the primary and secondary sides. To enable precise junction temperature monitoring, a novel approach based on bondable NTC sensors directly positioned in close proximity to the SiC devices is adopted. Additionally, the IPM is also equipped with integrated shunt resistors and measurement circuitry for overcurrent protection and DC-link voltage monitoring. Two different substrate materials and technologies, including Alumina and IMS, are manufactured for the IPM to evaluate the electrical and thermal performances.

- Modular bidirectional DAB-based DC/DC solution with high-frequency insulation It is equipped with the IPM and designed to operate at a rated power of 25 kW and high switching frequency (100 kHz) within wide input (600÷950 V) and output (600÷900 V) voltage ranges, ensuring bidirectional power flows and efficiencies greater than 96% for most operating conditions (98.5% peak efficiency).

- Modular Active Front End (AFE) solution with bidirectional power flow capability Designed with a rated power of 25 kW, it ensures the applicability of high-power bidirectional AFE solutions in three-phase electric grids through a modular and compact design, capable to achieve an output power of 50 kW through parallelization. A dedicated control strategy is implemented to manage common-mode currents on the shared DC link, enabling system scalability.

- Mobile buffer emergency battery system With a rated energy capacity of 20 kWh and 50 kW discharge capability, it is directly integrated within the charging infrastructure to provide backup energy for electric vehicle charging in case of grid outages and enabling ancillary grid services.

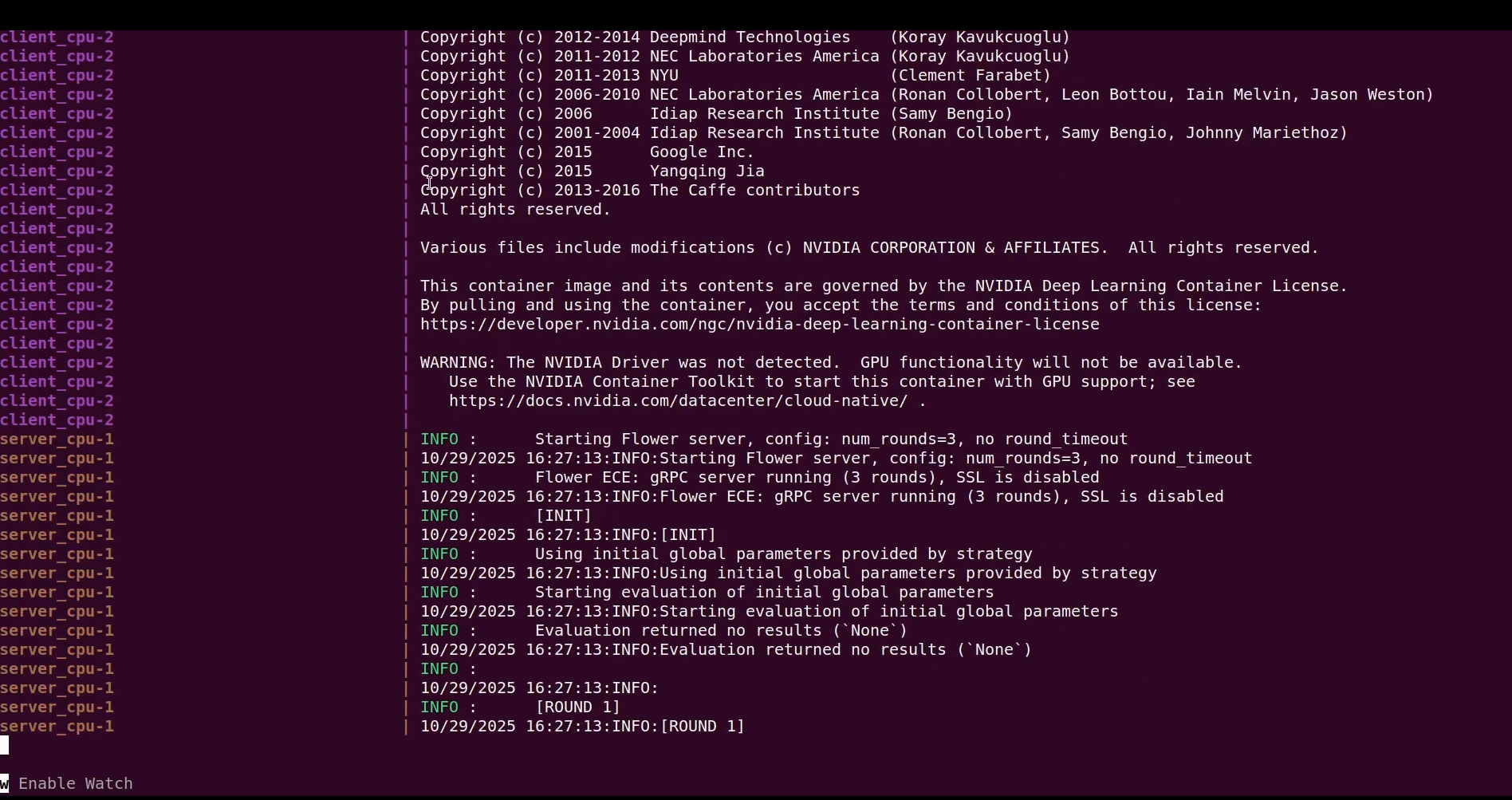

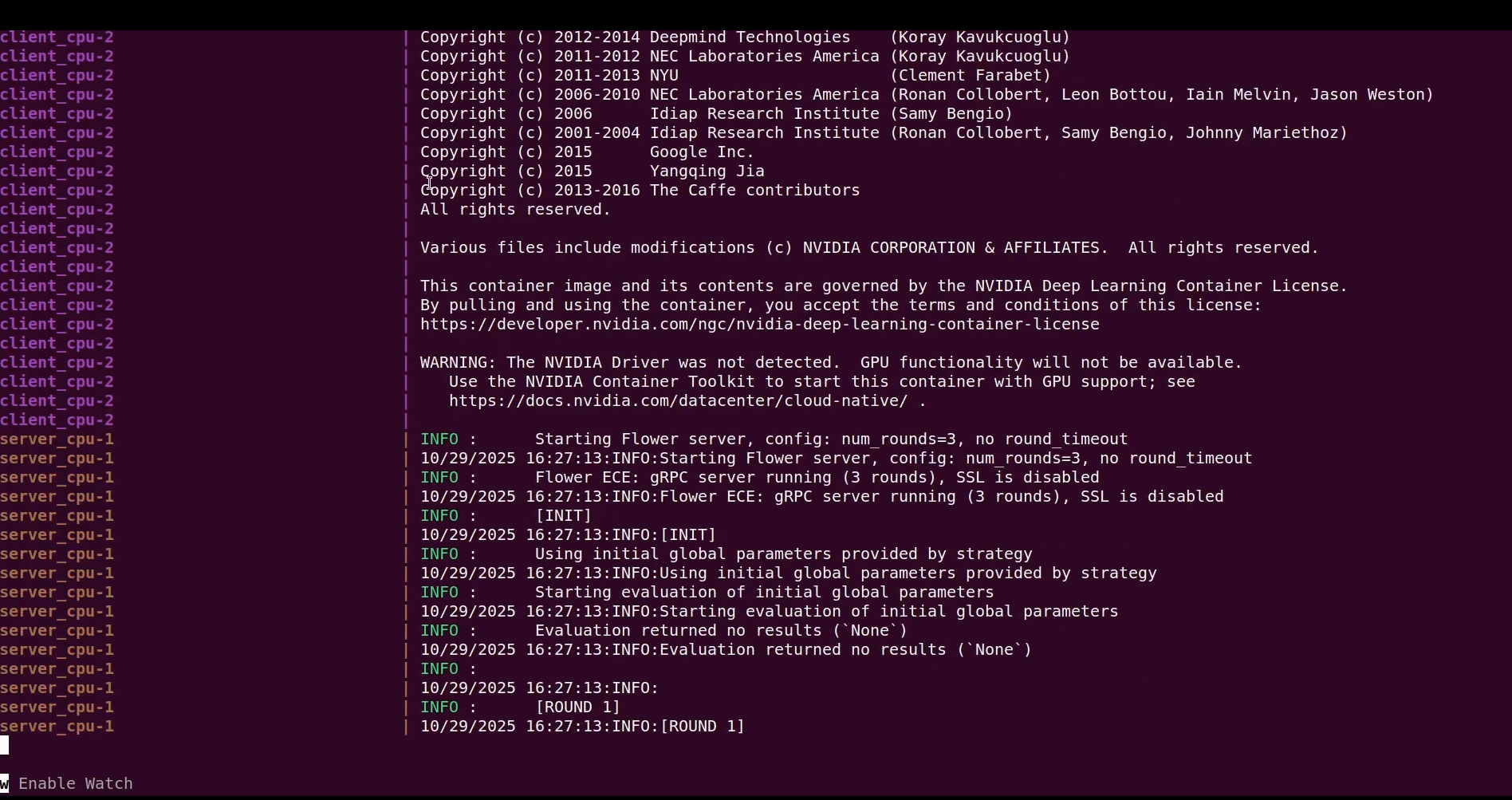

UC 1.7 - System of Systems - Demo A

by: Kaspars Ozols

from: ELEKTRONIKAS UN DATORZINATNU INSTITUTS

As one of the UC1.7 demonstrators, this demonstrator showcases an additional Differential Privacy (DP) protection module for the Federated Learning (FL) system, highlighting the benefits of enhanced privacy. The demonstrator illustrates the AI module’s training process using the CALCE dataset to estimate a battery’s Remaining Useful Life (RUL). The DP module is implemented with the OPACUS DP library and can be toggled "on" or "off". Multi‑client FL training is simulated with separate processes within a single Docker container. Protection levels can be monitored via epsilon values (the ε‑privacy budget), which the system calculates at the end of each training cycle.

from: ELEKTRONIKAS UN DATORZINATNU INSTITUTS

As one of the UC1.7 demonstrators, this demonstrator showcases an additional Differential Privacy (DP) protection module for the Federated Learning (FL) system, highlighting the benefits of enhanced privacy. The demonstrator illustrates the AI module’s training process using the CALCE dataset to estimate a battery’s Remaining Useful Life (RUL). The DP module is implemented with the OPACUS DP library and can be toggled "on" or "off". Multi‑client FL training is simulated with separate processes within a single Docker container. Protection levels can be monitored via epsilon values (the ε‑privacy budget), which the system calculates at the end of each training cycle.

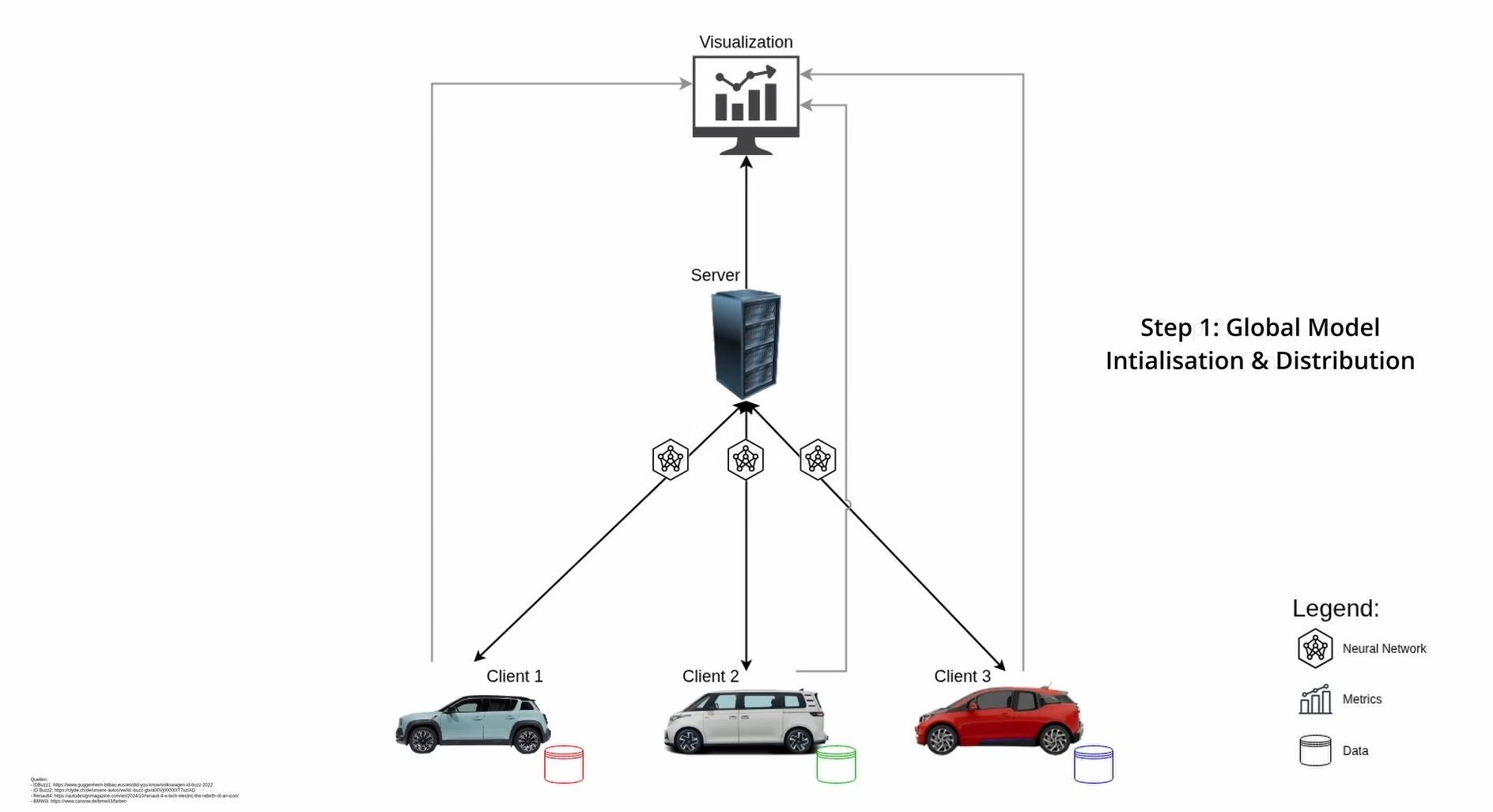

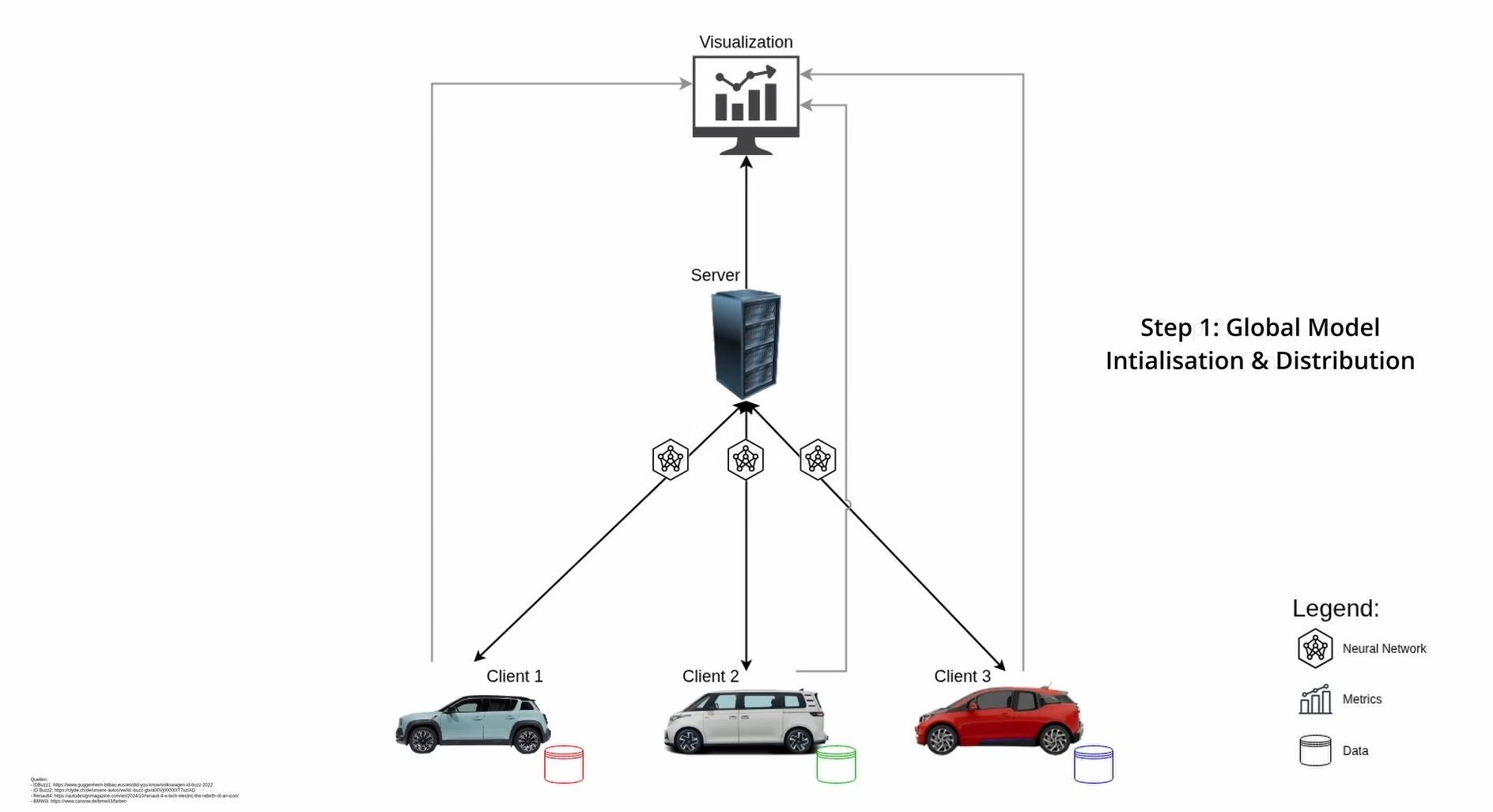

UC 1.7 - System of Systems - Demo B

by: Tobias Schafberger

from: Ostbayrische Technische Hochschule (OTH) Amberg-Weiden

One demonstrator of UC1.7 will highlight the benefits of Federated Learning, applied to estimate the Remaining Useful Life (RUL) of batteries using data from a simulated EV fleet. To achieve this, meta-models for the EV and its battery are created to generate battery ageing data. This data is then processed and used to train AI models through Federated Learning. The complete pipeline—from data generation and processing to training with FL—will be deployed both on edge devices and on a high-performance computer. Finally, key metrics and insights from the FL process will be presented in an interactive dashboard.

from: Ostbayrische Technische Hochschule (OTH) Amberg-Weiden

One demonstrator of UC1.7 will highlight the benefits of Federated Learning, applied to estimate the Remaining Useful Life (RUL) of batteries using data from a simulated EV fleet. To achieve this, meta-models for the EV and its battery are created to generate battery ageing data. This data is then processed and used to train AI models through Federated Learning. The complete pipeline—from data generation and processing to training with FL—will be deployed both on edge devices and on a high-performance computer. Finally, key metrics and insights from the FL process will be presented in an interactive dashboard.

UC 2.1 - Flow battery power electronics

by: Jiajun Cen

from: Aqua Battery

AquaBattery is deploying a 5 kW / 50 kWh pilot system at Deltares in Delft (NL) to demonstrate its innovative saltwater flow battery based on table salt within the PowerizeD EU project. The installation is directly connected to Deltares’ research facilities. It is designed to test and learn how long-duration energy storage can enable renewable integration in a behind-the-meter setting. As part of PowerizeD, the pilot acts as a real-world validation site for a novel high-efficiency DC-DC converter tailored for asymmetric charge and discharge profiles, while also serving to test and refine advanced control methodologies aimed at improving round-trip efficiency, extending system lifetime, and enhancing overall reliability

from: Aqua Battery

AquaBattery is deploying a 5 kW / 50 kWh pilot system at Deltares in Delft (NL) to demonstrate its innovative saltwater flow battery based on table salt within the PowerizeD EU project. The installation is directly connected to Deltares’ research facilities. It is designed to test and learn how long-duration energy storage can enable renewable integration in a behind-the-meter setting. As part of PowerizeD, the pilot acts as a real-world validation site for a novel high-efficiency DC-DC converter tailored for asymmetric charge and discharge profiles, while also serving to test and refine advanced control methodologies aimed at improving round-trip efficiency, extending system lifetime, and enhancing overall reliability

UC 2.3 - LED driver and LV DC distribution grid

by: Eugen De Mol

from: SIGNIFY NETHERLANDS BV

The competitive lighting market landscape requires the fast introduction of a first generation 1800W LED driver. Therefore, next to working on building blocks for next generation LED drivers, already during the PowerizeD project, Signify will develop the first 1800W LED driver with an electrical and thermal performance beyond best-in-class LED drivers currently in the market for this application field. This product, called Xitanium 1800W, is to be fully released early 2026.

Target applications for the Xitanium 1800W are indoor and outdoor sport fields, but also large areas like airports and cargo ports.

from: SIGNIFY NETHERLANDS BV

The competitive lighting market landscape requires the fast introduction of a first generation 1800W LED driver. Therefore, next to working on building blocks for next generation LED drivers, already during the PowerizeD project, Signify will develop the first 1800W LED driver with an electrical and thermal performance beyond best-in-class LED drivers currently in the market for this application field. This product, called Xitanium 1800W, is to be fully released early 2026.

Target applications for the Xitanium 1800W are indoor and outdoor sport fields, but also large areas like airports and cargo ports.

UC 2.4 - Home and mobile PV with storage

by:Georg Heiland

from: FINEPOWER GMBH

The demonstrator shows an improved battery storage system for private households, including power electronics and a low-voltage battery. The project-related innovations are an efficiency increase, extended functionality and increased power density. The efficiency is increased by an additional hardware auxiliary circuit and corresponding software-created control method, the functionality should be extended in terms of grid and load analysis as well as state of health analysis of the battery, improving by special control algorithms in terms of healthy charging and discharging current waveforms. Besides that, the power density of the whole power electronics unit is increased by designing a compact heatsink structure applicable to 3D metal printing technology.

from: FINEPOWER GMBH

The demonstrator shows an improved battery storage system for private households, including power electronics and a low-voltage battery. The project-related innovations are an efficiency increase, extended functionality and increased power density. The efficiency is increased by an additional hardware auxiliary circuit and corresponding software-created control method, the functionality should be extended in terms of grid and load analysis as well as state of health analysis of the battery, improving by special control algorithms in terms of healthy charging and discharging current waveforms. Besides that, the power density of the whole power electronics unit is increased by designing a compact heatsink structure applicable to 3D metal printing technology.

UC 3.1b – Intelligent gate driver for industrial inverter

by: Sebastian Rode and Dirk Rudolph

from: TUD – Dresden University of Technology

The UC3.1b demonstrator addresses advanced gate driver concepts for industrial inverters. It enables flexible dv/dt control and current balancing in parallel power devices, supporting both IGBTs and SiC MOSFETs. Two complementary methods – a controllable gate-emitter voltage source and a constant current source – are demonstrated. Furthermore, different approaches for current sensing are integrated and validated, including shunt-based measurement and a novel AMR sensor. Together, these developments contribute to improved robustness, efficiency and flexibility in next-generation industrial drives.

from: TUD – Dresden University of Technology

The UC3.1b demonstrator addresses advanced gate driver concepts for industrial inverters. It enables flexible dv/dt control and current balancing in parallel power devices, supporting both IGBTs and SiC MOSFETs. Two complementary methods – a controllable gate-emitter voltage source and a constant current source – are demonstrated. Furthermore, different approaches for current sensing are integrated and validated, including shunt-based measurement and a novel AMR sensor. Together, these developments contribute to improved robustness, efficiency and flexibility in next-generation industrial drives.

UC 3.2 - Hyper-sensorised digital drive - Demo A

by: Jesús Cantero Martínez

from: FAGOR AUTOMATION S COOP

Buck Converter demonstrator: It is a power converter that dynamically regulates the DC bus voltage via CNC control to match the operational requirements of the motor. Inverter demonstrator It is a modular speed controller that integrates a high-resolution digital current sensing acquisition system, coupled with an optimized decimation algorithm.

from: FAGOR AUTOMATION S COOP

Buck Converter demonstrator: It is a power converter that dynamically regulates the DC bus voltage via CNC control to match the operational requirements of the motor. Inverter demonstrator It is a modular speed controller that integrates a high-resolution digital current sensing acquisition system, coupled with an optimized decimation algorithm.

UC 3.2 - Hyper-sensorised digital drive - Demo B

by: Jesús Cantero Martínez

from: FAGOR AUTOMATION S COOP

The developed framework enables the prediction of the remaining useful life of electronic devices by leveraging run-to-failure data and advanced machine learning techniques. It offers a user-friendly interface to configure models such as recurrent neural networks and mixture density networks, supports ensemble learning with automated optimization, and provides recommendations through fuzzy logic inference. In addition, it allows transfer learning to improve efficiency and accuracy, and can deliver online, real-time predictions via a REST API, making it a versatile tool for prognostics and health management in power electronics.

from: FAGOR AUTOMATION S COOP

The developed framework enables the prediction of the remaining useful life of electronic devices by leveraging run-to-failure data and advanced machine learning techniques. It offers a user-friendly interface to configure models such as recurrent neural networks and mixture density networks, supports ensemble learning with automated optimization, and provides recommendations through fuzzy logic inference. In addition, it allows transfer learning to improve efficiency and accuracy, and can deliver online, real-time predictions via a REST API, making it a versatile tool for prognostics and health management in power electronics.